At the Shanghai International Auto Show in April this year, the century-old Dana, which has a full say in the transmission system, officially unveiled a comprehensive electrification lineup in the parts exhibition area. This also means that in the coming time, Dana will officially enter the research and development of the transmission system of the new energy power industry-according to Dana’s plan, Dana’s electric drive technology will be put into production in China in 2020 .

The transformation of a traditional parts industry in the new energy era has officially begun.

Parts companies are the cornerstone of the automobile industry. It seems that there is no parts company like Dana, which is widely recognized by vehicle manufacturers and well-known by a large number of car enthusiasts. Therefore, when Dana officially entered the field of electrification, it naturally gained the widest recognition.

Strictly speaking, Dana’s electrification process originated in the late 1960s. At that time, Dana invested in the development of hybrid power systems with a forward-looking view. In the early 21st century, Dana also carried out similar research and development. However, it is only in recent years that Dana’s electrification process has truly shown the scale of industrial development. The biggest difference between the development of industrial products and forward-looking technology is that the standard for evaluating the maturity of the former is Based on the premise of mass production.

As a century-old company, Dana’s product line has long been no longer limited to the transmission field. When the era of electrification comes, the development trends presented by Dana are also diversified. At present, Dana has successfully launched products such as Spicer® Electrified™ electric drive system and Long ® thermal management system in the fields of electric drive system and thermal management system, and has the ability to provide a complete set of drive system solutions for vehicle manufacturers and power supply thermal management solutions.

This also means that an electrified Dana is becoming a major power system supplier and solution provider for new energy vehicles.

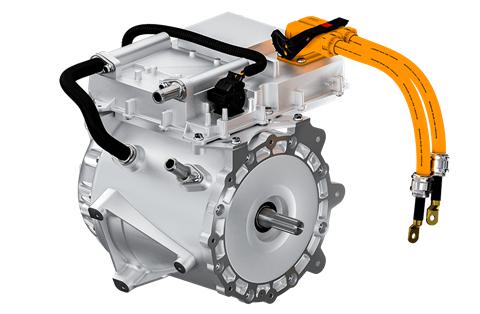

In the field of transmission, the enhanced TM4 MOTIVETM motor and inverter officially released by Dana at this year’s Shanghai International Auto Show are its main transmission products in the new energy era.

The enhanced TM4 MOTIVETM motor and inverter is a three-in-one turnkey solution for new energy drives provided by Dana for automobile companies, including electric motors, inverter algorithms and mechanical drive axles. The advantage of this system lies in its high degree of integration and friendliness to layout space. It is reported that in terms of size, the integrated Dana inverter is 33% smaller than the previous generation of products. The weight of the whole combination is 50 kg, and the maximum rated power output can be expanded to 150 kW and 11,000 rpm. /min level.

This system can independently provide new energy solutions for small passenger cars with transverse engine front-wheel drive platforms, and can also provide new energy electric drive solutions for mid-to-high-end passenger cars with longitudinal engine rear-wheel drive platforms. If the vehicle layout space permits, the TM4 MOTIVETM motor and inverter can also be operated in series to meet the demand for models with higher body weight, making it capable of being applied to light commercial vehicles.

In the field of off-highway vehicles, Dana also has a complete set of turnkey solutions for hybrid drive systems. However, it is not the focus here.

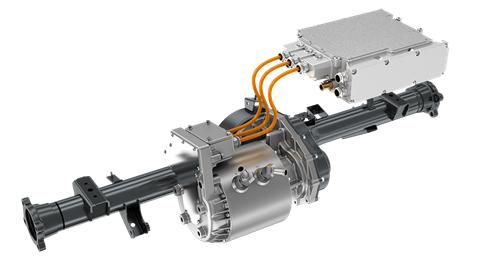

From a technical point of view, Dana’s electrification process in the traditional power field is gradually evolving on the basis of Dana’s traditional basic advantages. In the process of electrification, Dana first relied on its traditional advantages to launch a set of reducer assemblies for electric drive axles. Different from the traditional axle, the mechanical structure of the electric drive axle provides a more friendly electric motor accommodation space, making it possible to integrate the electric motor with the drive axle.

Compared with drive axles, electric motors are not Dana’s advantageous industry. Therefore, the way Dana chose was to acquire TM4, a subsidiary of Hydro-Québec, thereby obtaining technical and product support for TM4’s electric motors, generators, power electronic equipment, and control systems. Subsequently, TM4’s electric motor technology was integrated into Dana’s electric drive axle, so this returned to Dana’s traditional advantages. In the subsequent merger and acquisition with the Italian SME Group, it obtained the foundation of low-voltage AC induction motors, reluctance synchronous motors and inverters. Dana has thus obtained a series of and systematic motor technology.

In this way, on the basis of the original mechanical transmission system, Dana built the Spicer® Electrified™ series of electric drive products. In the future, the Chinese market will become the main market for Dana to expand in the field of new energy. As a result, Dana has added five new factories in China.

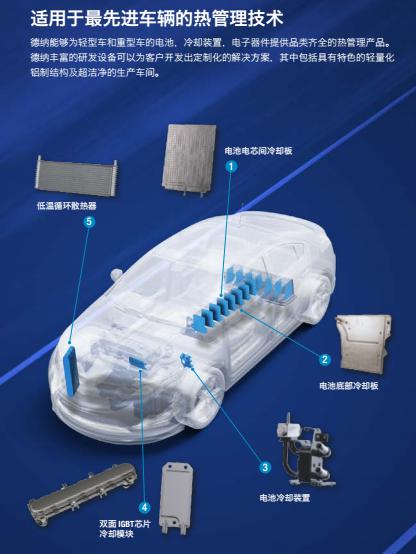

In addition to the field of transmission, Dana’s electrification process has also expanded to the field of thermal management. The expansion of this field benefited from Dana’s business in complete vehicle cooling systems. Dana’s Long ® thermal management products have been further refined into battery inter-cell (IC) cooling units, battery bottom cooling plates commonly used in hard case battery assemblies, battery cooling devices using refrigerant/coolant heat exchange devices, etc. . The debut of such a cooling system also means that Dana has entered the level related to the battery field in the process of electrification.

Obviously, Dana is optimistic about the new energy power market, and its electrification road integrated with superior resources also makes the solutions it can provide have diversified characteristics. In addition to pure electric power, Dana’s electric drive products can also be used in hybrid power systems. With such an industrial layout, the new energy vehicle electric drive system solution that Dana can provide to customers will also be the most optimized solution.